tail gas analyzers|ametek 888 manual : importing Cooled Sample Probe Condenses Sulfur Directly In Process Line to Minimize Risk of Analyzer Plugging. Closed-Coupled Mounting for < 10 Sec Response. No Span Gas, MP Steam, or . webSubsidiary of Opinodo ApS | Svanevej 22, 2nd floor | 2400 Copenhagen NV | Denmark |

[email protected] .

{plog:ftitle_list}

Resultado da 30 de set. de 2021 · The free-to-play football simulation game will have weekly online challenges amongst other new features ahead of its first major .

Designed specifically for monitoring H2S and SO2 in sulfur recovery tail gas, the 888 analyzers are built on more than 40 years of field-proven application experience, and provide an ideal solution for the hydrocarbon processing . Direct coupled tail gas and pit gas analyzer for sulfur recovery units. Monitors H 2 S, SO 2 , COS and CS 2 and calculates air demand. .900 Tail Gas-Air Demand Analyzer. Using high-resolution ultraviolet (UV) technology in a dual-beam, multiple-wavelength configuration, the 900 is specifically designed to meet the demanding analytical requirements of .The 888, the successor of the 880 NSL, uses field-proven and highly reliable UV technology to accurately monitor the H2S and SO2 concentrations in sulfur recovery tail gas. This compact, .

Cooled Sample Probe Condenses Sulfur Directly In Process Line to Minimize Risk of Analyzer Plugging. Closed-Coupled Mounting for < 10 Sec Response. No Span Gas, MP Steam, or .To analyze the chemical composition of the tail gas, the TLG-837 uses an analysis method known as ultraviolet-visible (UV-Vis) spectroscopy. The system measures a high-resolution .

The 888 utilizes ultraviolet (UV) spectroscopy to accurately monitor hydrogen sulfide (H 2 S) and sulfur dioxide (SO 2) concentrations in sulfur recovery tail gas. The analyzer delivers next-level reliability, with automatic flow control, flange .The Bridge Analyzer 4 gas analyzer measures Carbon Monoxide (CO), Carbon Dioxide (CO2), Fuel Dependent Hydro Carbons (HC), and Oxygen (O2). The analyzer comes in a hard case with all accessories as a complete, ready-to .A high-performing tail gas analyzer must therefore sustain accuracy when the ratio is outside the expected range (‘off-ratio’ conditions). In a multi-wave photometer, the response to concentration change is limited by a single .Peaks / Tail Gas Unit Bypass • SRU Fine-Tuning Limited By Slow Feed Change Detection DAD Using 2 Brimstone 943TGX Analyzers • st1 Measurement (DAD) at Outlet of 1st Condenser . Tail Gas Analyzer for Air Demand Control [email protected] | +1 (403) 252-8470 | www.galvanic.com Rev. August 2019 | Specifications Subject to Change Without .

The tail gas analyzer and feedback control accounts for 2% to 4% of recovery efficiency and contributes more to overall SRU performance than does the third converter (Fig. 2). 2 . Fig. 2. Efficiency as a Function of Excess Air . In a plant designed for 94 % recovery, a 1 % loss of recovery will be observed if there is a 6 %Industry's Leading Tail Gas Analyzer. Fast, continuous reading. Total system response time under 10 seconds. Superior accuracy. ±1% full scale. Excellent performance during upset / off-ratio conditions. Accurate if 100:1 H 2 S:SO 2 1:20. Additionally measure COS and CS 2. Using advanced multi-component analysis.The Bridge 4 gas analyzer & 5 gas analyzer are designed to measure tailpipe exhaust emissions in order to maximum engine performance and identify compliance issues. CO or CO/H-C gas analyzers cannot measure O2 & CO2 in the exhaust gas stream that could be caused by an extraneous air leak (See included technical support note).The ammonia (NH 3) gas is injected to remove the NOx and thus reduce the NOx concentration in the stack flue gas.With conventional NH 3 analyzers that perform measurements indirectly, NH 3 concentrations are obtained through a sampling system. Therefore, there are problems with the maintenance and running costs of the sampling system, and time delays in measurement.

The development of sulfur recovery for oil refining, gas processing and coke oven plants was largely driven by environmental regulations. The Claus sulfur recovery unit (SRU) and tail gas treating unit (TGTU) require a suite of process gas analyzers to operate safely, protect the catalyst/amine at high efficiency and meet environmental regulations for sulfur dioxide .

ametek model 888

ametek 888 manual

888 Sulfur Recovery Tail Gas Analyzer AMETEK Process Instruments has been the leader in tail gas analysis for over 40 years, with more than 1,100 installed 880 NSL analyzers and more than 100 million hours of run time. The 888, the successor of the 880 NSL, uses ield-proven and highly reliable UV technology to accurately monitor theTail Gas Analyzer User Interface Manual including installation, maintenance and troubleshooting, spare parts, specifications, drawings of the overall system, and working from the User Interface. Additional information about the 888L Tail Gas Analyzer is .

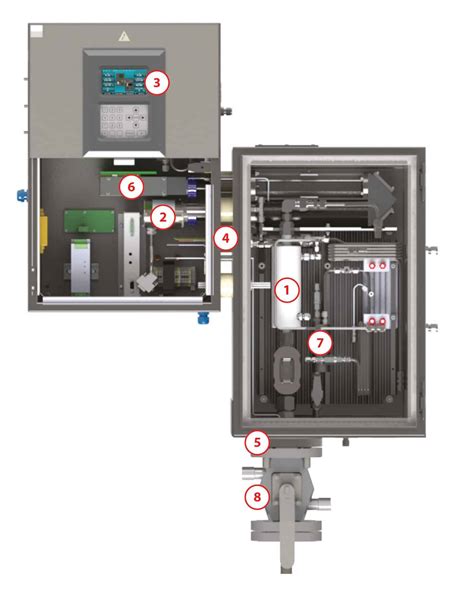

OVERVIEW Model 888 Tail Gas Analyzer uses photometric analysis to The AMETEK Model 888 Tail Gas Analyzer continuously monitor hydrogen sulfide, H S, and sulfur dioxide, SO , pres- ent in the tail gas stream of a Claus plant. Electronics Enclosure. Page 18: Electronics Enclosure The electronics enclosure houses the source and detector assemblies.

The Claus sulfur recovery unit (SRU) and tail gas treating unit (TGTU) require a suite of process gas analyzers to ensure safe operation, high efficiency, and meet environmental regulations. The development of sulfur recovery processes for oil refining, gas processing and coke oven plants began as a need to meet environmental regulations and .[1] DS-004A: TLG-837 Tail Gas / Air Demand Analyzer The world’s safest tail gas analyzer. The TLG-837 continuously measures the chemical concentrations of H 2 S, SO 2, COS, and CS 2 in the Claus process tail gas stream. Using the patented in situ DEMISTER sampling probe and a full-spectrum UV-Vis spectrophotometer, this systemApplications include: acid feed gas, tail gas, sulfur pit gas, and tail gas treatment. SRU Acid Feed Gas Analyzers; IPS-4; 931 Single Gas H 2 S Analyzer (opt. + H2 and HC) 993X; SRU Tail Gas Analyzers 888-Sulfur Recovery Tail Gas Analyzer; 900 Tail Gas/Air Demand Analyzer; Tail Gas Treating Unit Analyzers; 931 Single Gas H 2 S Analyzer (opt .

Tail Gas/Air Demand Analyzer. Chlorine Process Analyzer. Feed Gas (Acid Gas) H 2 S Analyzer. Measuring Fluorine Gas in Specialty Gases. Hydrogen Analyzer. Total Sulfur Gas Analyzers. Water in Solvent Analyzer. Measuring .Measurement: H 2 S, SO 2, COS, CS 2 Range: H 2 S 0-2%, SO 2 0-1%, COS 0-5000 PPMV, CS 2 0-5000 PPMV Purpose: To control the trim air flow to the burner Analyzer: TLG-837 Tail Gas/Air Demand Analyzer The effluent .AMETEK PROCESS INSTRUMENTS PRODUCT DATA SHEET key benefits • Auto-flow control, an industry first • Flange temperature alarm to warn of non-functioning steam trap • Rated to 60°C (140°F) ambient temperature • No .

The Ametek Model 888 Sulfur Recovery Tail Gas Analyzer, the successor of the 880 NSL uses field-proven and highly reliable UV technology to accurately monitor the H 2 S and SO 2 concentrations in sulfur recovery tail gas. This compact, rugged analyzer mounts directly on the process pipe, eliminating the complexity and safety issues of fiber optic coupled photometers.A trace oxygen analyzer offering superior protection for a range of industrial applications through a rapid response to process changes. With a modular design for easy upgrades and field service, the TM2000 can accurately respond from atmosphere to low parts per million (ppm) in just seconds, serving a wide measurement range from 0.1 ppm to 100% O 2.The world’s safest tail gas analyzer. TLG-837 continuously measures the concentrations of H 2 S, SO 2, COS, and CS 2 in the Claus process tail gas stream. Using the patented in situ DEMISTER sampling probe and a full-spectrum UV-Vis spectrophotometer, this system provides extremely fast, accurate response for tight process control.

We offer the world’s safest tail gas analyzer which continuously measures the concentrations of H2S, SO2, COS, and CS2 in the Claus process tail gas stream. Using the patented in situ DEMISTER sampling probe and a full-spectrum UV-Vis spectrophotometer, this system provides extremely fast, accurate response for tight process control. The analyzer is a fully solid state .Model: OMA Feed Gas (Acid Gas) H 2 S Analyzer While tail gas analysis measures the H 2 S:SO 2 ratio after the furnace to calculate air demand correction, a feed forward analysis system measures the H 2 S concentration in the acid feed gas before the furnace to preemptively adjust air demand based on the real-time feed gas H 2 S level. While tail gas analysis provides the .[1] DS-004A: TLG-837 Tail Gas / Air Demand Analyzer The world’s safest tail gas analyzer. The TLG-837 continuously measures the chemical concentrations of H 2 S, SO 2, COS, and CS 2 in the Claus process tail gas stream. Using the patented in situ DEMISTER sampling probe and a full-spectrum UV-Vis spectrophotometer, this systemSuitable Analyzer; Tail Gas from Claus Process: H 2 S (hydrogen sulfide) 0-4,000 PPMV: OMA-300 Process Analyzer: H 2 (hydrogen) 0-10%: Introduction. The purpose of a tail gas treatment unit (TGTU) is to maximize the conversion of sulfur compounds to H 2 S. With an efficiently run TGTU, sulfur recovery efficiency can be increased up to 99.99%.

AMETEK Process Instruments is the acknowledged leader in process analyzers for sulfur recovery units. It currently has an installed base of more than 1,100 model 880 tail gas analyzers worldwide with over 100 million hours of run time.

World’s safest tail gas analyzer. Continuously measures the concentrations of H 2 S, SO 2 , COS, and CS 2 in the Claus process tail gas stream. Using the in situ special sampling probe and a full-spectrum UV-VIs spectrophotometer, this system provides extremely fast, accurate response for tight process control.BULLETIN 880 Model 880-NSL Tail Gas Analyzer THE NEED Accurate, reliable measurement of H2S and SO2 in the tail gas from a Claus sulfur recovery plant is critical. Unfortunately, tail gas analysis has historically been one of the most difficult applications because of common problems with sample line plugging due to sulfur vapors present in the .

ametek 880 nsl

lifeproof next review drop test

Hotéis e resorts. Papagayo Beach Resort. Construída no topo da área de Jan Thiel, as espaçosas villas do Papagayo Beach Resort exibem um toque moderno com uma .

tail gas analyzers|ametek 888 manual